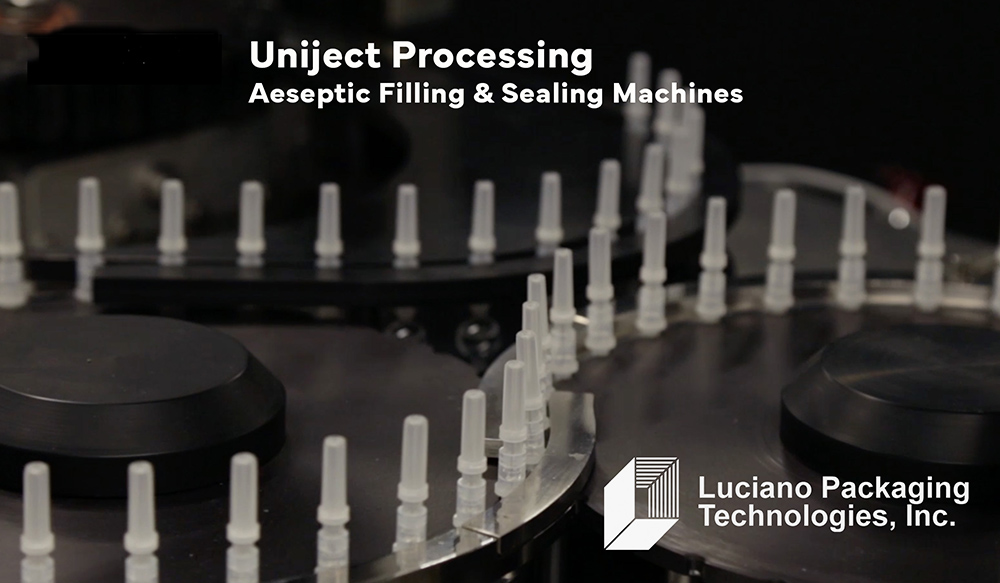

The Uniject machine processes reels of filled and sealed Unijects. The basic machine performs the following functions.

- Inspect for the presence of liquid

- Apply pressure sensitive labels3

- Cut individual Unijects out of the strip

- Reject Unijects that fail inspection

- Dispense finished, accepted, Unijects

Unijet Model # 120/150

Continuous motion carries the product through fill detection and labeling. Die cutting is done intermittently, producing, four products per cycle at up to 37.5 cycles per minute, so that 150 Unijects are finished per minute. The transiton from continuous to intermittent motion is handled internally within the machine without loss of leading or trailing products. The machine was designed to use a minimum of compressed air, and the cutting press is driven by a servo motor. The control is by a PLC, and the operator interface is a color touch screen. The machine is self-diagnostic, so that if any problem occurs such as a material jam, consecutive inspection failures, etc., a graphical message display will explain why the machine stopped, to enable prompt operator attention. An OSHA compliant saftey enclosure surrounds the mechanical components, with doors interlocked so that the machine will not run when the door is open. The machine is built of non-corrosive materials, in a design amenable to a pharmaceutical production enviroment. The base machine will be supplied with tooling for one product size and one unwind stand for coiled Uniject strips.