Luciano Packaging Technology Inc. designs and installs custom machinery worldwide. Luciano Packaging is unique in the industry because of its ability to find innovative and cost effective solutions to the most difficult problems in packaging. Actual, custom machinery is developed, to order, using the latest technologies available in in sensors, actuators, intelligent motions and controls. Advanced manufacturing methods are also used as required. We work with clients throughout the United States and world wide. For over 40 years we have designed, assembled and delivered custom machinery to address real world packaging requirements and opportunities.

What Our Custom Machinery Can Do

Machines designed and built by the Luciano team include:

- Liquid Filling

- Aseptic Filling For Parenteral Products

- Assembly Machines

- Tablet Inspection and Handling

- Blister Packaging

- Bag Loading

- De-Palletizing

- Pouching

- Product and Package Handling/Collating

- Labeling and Die Cutting

- Printing and Inspection

- Conveying

Industries We Serve

- Pharmacuetical

- Medical Device

- Food and Beverage

- Chemical Products

- Cosmetics

- Household Products

- Personal Care Products

- Product Distributors

Examples Of Custom Machinery We Have Designed and Fabricated

About This Liquid Filling Machine

Medical pouch with spout; foil laminate structure; mass flow filling.

About This Aseptic Filling Machine

Aseptic filling in a RABS for molded plastic vials with in-mold stopper. Features filling through custom non-corking needle nozzles through stopper with subsequent laser cauterizing.

About This Assembly Machine

Stapler assembly processes including E-Clip application assembly inspection and grease application. Featuring the UR-5e Universal Collaborative Robot for product transfers and presentation for processes. Also featured is the Teledyne DALSA vision inspection system for E-Clip application assurance. A recirculating puck handling system provides seamless integration into exiting production line. System processes up to eight (8) staplers per minute and replaces two (2) operators performing stressful repetitive operations.

About This Inspection Machine

Luciano Packaging Technologies, Inc. Hypak Inspection Machine including automatic needle shield and flange inspection and 2-station semi-automatic particle and cosmetic inspection. Features Beckhoff system controls, Halcon vision, and Adept robot.

About This Bag Loading Machine

KEY-PAK “EL” Series of Vertical Form/Fill/Seal Machines include four single tube and two twin tube models. The single tube machines are available in 8″ or 12″ maximum bag widths. In addition, two twin tube models are available providing production speeds up to 160 bags per minute. Learn more about our Key•Pak bagging line of products here

About This De-Palletizing Machine

Depalletizing wide mouth glass jars that were shipped overseas in open trays. Vision guided gantry robot features pallet elevating lift to reduce z-axis travel and height. Also includes tray disposal, slip sheet removal and jar particle cleansing wash.

About This Package Handling/Collating Machine

Glue Board collating and packaging. Integrated at the end of the converting line, the system operates at up to 720 boards per minute (6 lanes @ 120/min cycle); counts and collates with statistical weigh sampling in each lane, and transfers collated stacks into pucks for loading into corrugated cartoning machine.

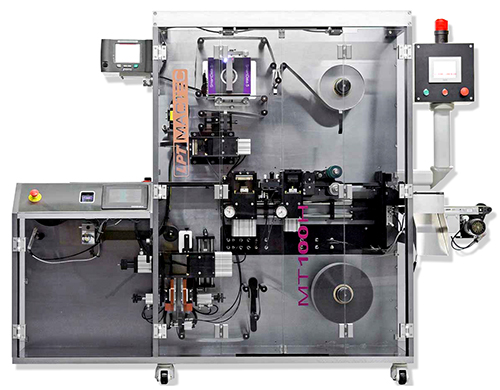

About This Labeling & Die-Cutting Machine

The UJ-120 is a finishing process machine for pre-filled and sealed Uniject syringe devices. The Uniject devices are pre-filled disposable syringes that that are primarily used for subcutaneous delivery of vaccines and other medicines. The syringe devices are formed, aseptically filled. and sealed on a web, and then delivered to the UJ-120 machine for finish processing. The machine labels the product on both sides (identity and compliance printed labels) , die-cuts the web to create individual devices, and inspects for fill, particles, proper labeling and printing, and proper die-cut. The devices are then robotically transferred onto a high voltage leak detection machine (Nikka Densok) at a rate of 120 devices per minute. The machine features Herma 400H labeling heads, Videojet laser printer, multiple Keyence vision systems, and custom designed toggle press and die-cut tooling.