Uniject Model UJ-120 Finishing Machine

Detailed Specifications:

- Fill Assurance

- Labeling (both sides)

- Label Printing (laser or inkjet)

- Die-cutting

- Needle Shield Inspection (presence, position)

- Cosmetic Inspection (label presence, placement, die-cut

- Print OCR Inspection

- Fully automatic particle inspection

- Automatic transfer to leak inspection (by others)

Continuous motion carries the product through fill detection and labeling. Die cutting is done intermittently, producing, four products per cycle at up to 30 indexes per minute, so that 120 Unijects are finished per minute. The transiton from continuous to intermittent motion is handled internally within the machine without loss of leading or trailing products. The machine was designed to use a minimum of compressed air, and the cutting press is driven by a servo motor. The control is by a PLC, and the operator interface is a color touch screen. The machine is self-diagnostic, so that if any problem occurs such as a material jam, consecutive inspection failures, etc., a graphical message display will explain why the machine stopped, to enable prompt operator attention. An OSHA compliant saftey enclosure surrounds the mechanical components, with doors interlocked so that the machine will not run when the door is open. The machine is built of non-corrosive materials, in a design amenable to a pharmaceutical production enviroment. The base machine will be supplied with tooling for one product size and one unwind stand for coiled Uniject strips.

Uniject Model UJFS-60 Aseptic Liquid Filling and Sealing Machine

Uniject filling and sealing machines process triple-bagged reels of sterilized Uniject devices through the de-bagging, shield inspection, filling, and sealing operations, along with powered re-winding. Our machines have been integrated with RABS and isolation enclosures, and are designed for aseptic operation and CIP sanitization. Standard filling is accomplished with peristaltic pump fillers, but positive displacement piston fillers have been used. The machines are available with single indexing, single head configuration, UJFS-30, and double indexing, two head configuration, UJFS-60.

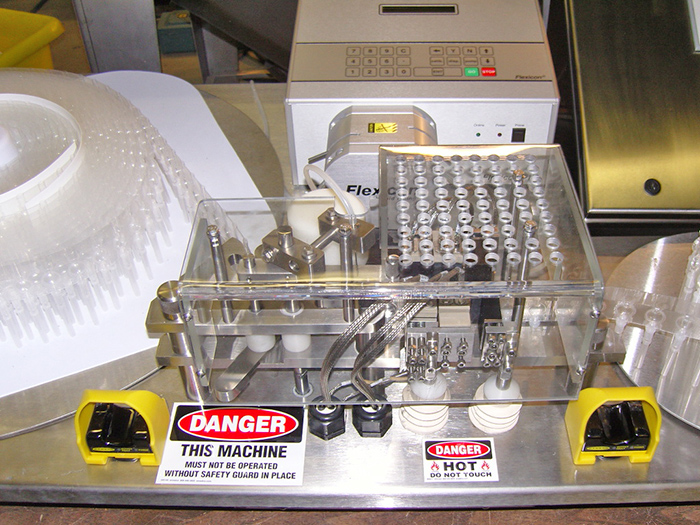

Semiautomatic tabletop machines for product development and stability testing are available and are designed to be used in a laboratory hood.